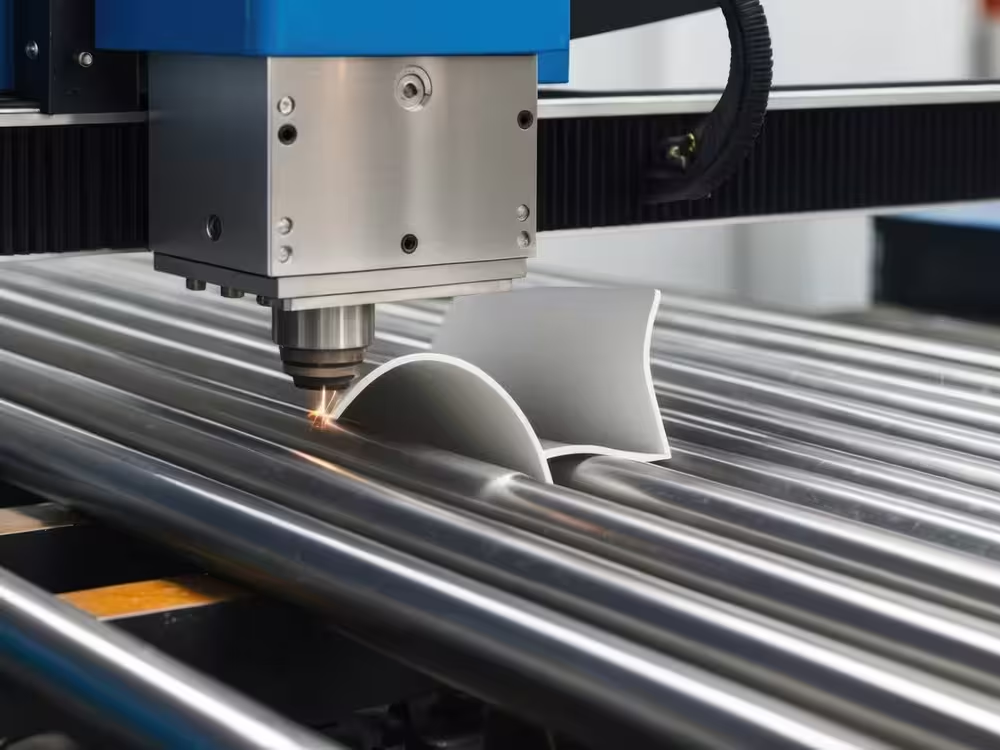

Laser CNC Metal Cutting Services for Precise and Fast Production

Achieving High Precision and Quality in Pole Production with Laser CNC Cutting Technology

We utilize Laser CNC cutting technology to ensure high precision and quality in pole production. This cutting method is ideal for complex and detailed projects, providing fast and effective solutions. Read our article to learn more about the features and advantages of Laser CNC cutting.

What is Laser CNC Cutting and Why is It Preferred?

Laser CNC cutting is a manufacturing technique that uses laser beams to cut various materials such as metal, wood, and acrylic with high precision. This method operates with a CNC (Computer Numerical Control) system, allowing error-free execution of pre-programmed designs. Particularly favored for detailed cutting tasks like pole production, this method minimizes material waste and ensures clean cuts.

Stages of Laser CNC Cutting

- Design Preparation: The cutting design is created in a digital environment and uploaded to the CNC machine.

- Cutting Process: The laser beam moves across the material, cutting according to the design.

- Final Inspection: Post-cutting, surface quality and measurements are checked to complete the process.

Advantages of Using Laser CNC Cutting

Laser CNC cutting offers numerous benefits over traditional cutting methods. Here are the key advantages of laser cutting technology:

- High Precision: Laser cutting performs even the finest details flawlessly, enhancing product quality.

- Fast Production: Automation enables rapid production, shortening project delivery times.

- Minimal Material Waste: It increases efficiency and reduces costs by keeping material waste to a minimum.

Reliable Laser CNC Cutting Services

At 2tmakina, we provide tailored solutions for your projects with modern CNC cutting machines and a team of experts. With our high-precision laser cutting technology, we deliver fast, quality, and reliable services for all types of projects. Contact us to learn more about laser cutting processes and to partner with us for your projects.

Contact

- Mimaroba Mah. Uğur Mumcu Cad. 12a/9 Büyükçekmece İstanbul/TÜRKİYE